MadMax's Future Pinball Table Detail Design Guide

…or “How to Create Realistic Pinball Tables”

Initial release, 12th September 2006

The HTML version of this guide can be found at this

URL:

http://www.futurepinball.com/forum/viewtopic.php?t=1862

Anyone can build a pinball table with Future Pinball.

It’s very easy to get something together that looks convincing because FP has

very realistic graphics and objects to work with. However, there are some

guidelines to follow if you want to build a table with truly realistic visuals,

and I’m taking you through them in this guide.

For starters, you should have some basic idea of what you

want to create since this guide is not for absolute beginners. But if you have

a table in the works and want to spice it up with some realistic detail, read

on.

1. The Beginning: The Real World

When designing a pinball table on the computer, the

best comparison you could have is a real pinball machine. Practically all of

the little tricks I’m about to show you bring your Future Pinball table closer

to a real machine since you will be recreating details which are common on

them, but often overlooked in FP. So if you have access to a pinball machine or

you can find detailed photos of one, you can always compare your work to the

real thing. A good photo resource is, of course, the Internet Pinball Database

at http://www.ipdb.org.

Future Pinball is a simulator and as such its essence

is detail and realism. The program provides enough models and functions to

build a truly realistic pinball table, but it isn’t always obvious how these

functions should be used. It starts with the placement of screws and ends with

custom-tailored details, like realistic ramps. A little creativity can even

substitute some missing features in FP, and some things I came up with will be

shown in this guide.

I have created a customized “new table” which has many

of the features implemented that I describe here. You can use the table for

research or to build your own creation. Since it’s basically an empty table

with some added stuff to quicker get you started, I won’t mind if you mess around

with it and use it as a base to build your own. Of course you can remove the

credits in the info, I just put them there so you know where this table came

from. ;-) The table can be downloaded here:

http://www.silverball-magic.com/FP/CustomNewTable_MadMax.zip

2. The Groundwork: Building a Solid Fundament

Once you have a table layout in mind, start with the

basics that make this layout work. That means, don’t go around placing plastics

and screws yet until you’ve created a playable and working layout of metal wall

guides, bumpers, target banks and ramps. But how can we add some realism to the

table when we are just in the first stage of construction?

Ball Trough:

The ball trough on FP’s default “new table” has a huge

unrealistic flaw – the exit to the plunger lane goes straight upwards from

inside the trough, kicking the ball up high into the lane and forcing the

player to wait a second for the ball to come down and rest on the plunger. This

is not only annoying on many otherwise fine tables, but it’s also not how a

real machine’s trough works. A real ball trough has a bend on the inside walls

which direct the ball so that it is kicked straight onto the outer wall of the

plunger lane, bouncing back and falling down instantly. The ball comes to rest

on the plunger within milliseconds and is ready to play.

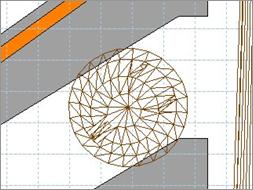

The modification to make to the ball trough is simple:

add a non-smooth shape point on

either trough wall and move the points close to the exit, then shape a bend

with them to force the ball horizontally out of the trough. See the picture for

reference.

You may get a better or worse ball serve depending on

how close you make the walls around the trough kicker and how far the kicker is

away from the exit. The default strength

of 3 should be enough to get the ball out quickly.

Plunger Lane:

Normally a plunger lane has a

metal protector on the right wall to prevent damage to the wall from served

balls. When shaping a short plunger lane with a diagonal exit, the whole wall

would be covered with a metal wall guide that would lead to the exit.

Normally a plunger lane has a

metal protector on the right wall to prevent damage to the wall from served

balls. When shaping a short plunger lane with a diagonal exit, the whole wall

would be covered with a metal wall guide that would lead to the exit.

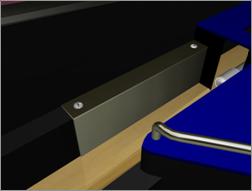

To build a protector like on a real machine, simply

create a metal wall guide with a

length of roughly 11 centimeters,

position it on the right wall, make a surface

of equal length that covers the guide and the wall and put it on top. You can

add Orn-Screw models to the surface

to simulate that the protector was screwed into the wall. Sphere map both the guide and the surface to make it look like

metal.

Flippers:

By default, the flippers are strangely shifted a little

upwards and don’t line up with the lane guides. Moving both flippers down by one millimeter (one tap on the down

arrow key) positions them perfectly.

Also, flipper strength and animation is a little

critical in the current release of FP. On normal strength, the flippers are

strong enough to get the ball up on high ramps even with a table slope of 8

degrees (which in fact are not 8 true degrees!), and increasing the

strength makes the flippers extremely strong, only useful for widebody tables

or high table slopes. However, it also makes the flipper movement more

realistic since they will appear to “snap” up quicker like on real machines,

and on very high strength settings there is even a slight improvement in ball

physics (center shots are easier and the ball takes better paths). It’s up to

you to figure out what suits your table best, but keep in mind that high

flipper strength can lead to uncontrolled air balls and malfunctioning ramps.

Rubbers:

When shaping a rubber around posts, try to make it as

smooth and hugging as possible. The rubber shouldn’t loosely sit on the posts,

but in fact be tightly strapped around them. Use the blue circle on posts in the editor view as a reference. The circle

represents the carving of a post where the rubber should sit in, so fitting the

rubber closely around the circle with at least three smooth shape points and one non-smooth ending point on each

side should give you a nice result. Also, rubbers never bow on a side; they

should be straight on every side of the shape they represent.

The default rubber offset

for star posts is 14, and 20 for the second rubber on double-carved posts.

Metal posts usually use an offset of 14 as well.

Posts:

One thing that Future Pinball

lacks is a Z-axis view, so you are forced to know the height of posts, rubbers,

guides and plastics in order to get it all together. When it comes to posts,

there are some differences in height

that should be watched:

One thing that Future Pinball

lacks is a Z-axis view, so you are forced to know the height of posts, rubbers,

guides and plastics in order to get it all together. When it comes to posts,

there are some differences in height

that should be watched:

star posts: 27 mm

rubber bumper posts: 29 mm

smooth plastic posts: various

In general there is one thing that is often overlooked

by designers. Star posts need to be affixed to the playfield with a long screw

on pinball machines, and this screw is also the holder for plastics which are

placed on top of the posts. There is an ornament model called Orn-Nut-Spacer which represents exactly

this post screw, and it should go into the center of every (translucent) star

post so it actually looks as if they were fixed to the playfield! But more

importantly, the nut on the screw (the spacer) which holds the post in place

adds a height of 2 millimeters to the

post, totaling in 29 millimeters just

like the metal wall guides and rubber bumper posts. If you place your plastics

on star posts later, you should always keep this in mind as you might want to

make sure that your plastic offset is

29 millimeters on every post/guide, be it a star post or not. And to get these

height compatible, you can use the spacer nut.

Metal Wall Guides:

These guides shape any lanes, loops or blockades on

your table. Aside from careful shaping there is one thing to watch out for if

you want to stay real: whenever two wall guides meet, put a post between them. The post acts as a

screw point for the plastic that will be put over the guides, and it will

smoothen out the otherwise sharp edge that would appear on meeting guides.

Adding a post to the end of a wall guide can also be useful if you put a ramp

next to it or if you want to add something like a target bank, which needs

posts on both sides.

Target Banks:

A standup (leaf)

target bank only needs a rubber

bumper post at each end of the bank to separate it from the rest of the

table. Also, since the bank will most likely be covered with a plastic later,

the posts act as screw points for the plastic.

A drop target bank

should have a single or double rubber

behind it to let the ball bounce back in case it hits a target which is already

down. The rubber should fully cover the length of the bank and be attached to

two star posts. A rubber bumper post at each end of the bank will keep the

outer drop targets from being hit from the sides, unless you want that to

happen. You can screw a plastic to these posts later to cover the bank just

like with standup targets.

Colours & Texturing:

Correctly colouring a pinball table can make a

difference between realism and oddity. I’ve seen some tables with true blue,

100% red and light green ramps, walls and plastics, and they looked like a

child’s toy. Decent colours make a

table realistic. But colouring in FP has an important effect on models and

textures as well.

For example, it’s never a good idea to work with

absolute values. If you want to make some-thing black, setting the RGB values to 0 is not a good idea since

it will ruin the 3D effect of the object – top and side will look identical and

will be hard to distinguish, but slightly upping the RGB values to 30 (very

dark gray) will give you a nice black object with a slight bright-ness

difference on the sides. Similarly, pure white should be used carefully as it

often makes objects look “glowing”. A very light shade of gray, like the one in

the custom colour table, is almost

perfectly white on most models and doesn’t have the glow effect.

When applying a texture to an object, the colour will

be layered over it and determine the tone of the texture. Using different

shades of gray you can determine how bright you want the texture to be. This is

especially important when using sphere

maps: a darker sphere map can be made brighter with white colouring while a

bright map can be toned down using dark gray.

An example: you want to

texture a spinner bracket with a sphere map. Normally the “chrome silver” map produces a rather dark and golden tone which

doesn’t look particularly polished. There are two alternatives: either you use

the “chrome white” map which is

essentially brighter, but looks a little dull because light reflections are

smoother. However, you could also keep using the silver map and change the

colour of the model to white, enhancing the brightness

of the map and reducing the gold.

An example: you want to

texture a spinner bracket with a sphere map. Normally the “chrome silver” map produces a rather dark and golden tone which

doesn’t look particularly polished. There are two alternatives: either you use

the “chrome white” map which is

essentially brighter, but looks a little dull because light reflections are

smoother. However, you could also keep using the silver map and change the

colour of the model to white, enhancing the brightness

of the map and reducing the gold.

Overall I’m using these textures and colours for the

following objects:

metal wall guides: chrome white, light gray (default)

wire guides, wire ramps, metal posts: chrome silver,

white

rubbers: light black (RGB 30, 30, 30), light gray

(custom colour table)

GI bulbs: bright olive (RGB 213, 213, 181)

bumpers: full colour for lit cap, balanced darker tone

for unlit cap, deep dark colour for skirt

plastics: dark or mixed colours

Lights & Flashers:

GI bulbs are a little tricky to set up.

First, don’t forget the ornament holes

under them and send them to the back. Make sure that any objects you want to

block the light are drawn in front of

the bulb, but that flasher bulbs should be drawn in front of everything to really flash over the table objects, creating

an “overbright” light effect. For white bulbs, the best and probably most

realistic colour is bright olive (RGB 213, 213, 181) since GI bulbs are rarely

pure white. Also, while the colour tone may seem a little dark, Future Pinball

will make it very bright in-game since bulbs have a radiosity and intensity

that will increase the brightness and make the colour “glow” a little. A nice radius for most bulbs is 64 millimeters although you might want

to up that a little depending on how much scattered light you want in an area.

For “naked flasher bulbs”,

i.e. flashers without a plastic dome, there’s a neat trick. Simply insert a

normal bulb, make it completely white

and set the radius very high, like 96 millimeters. The white colour and

radius will make this bulb extremely bright. Don’t forget to draw this bulb in front of any object as

you would do it with flashers, so the bright flash will overdraw any objects.

Then flash this bulb using the Flash-ForMs

script function, and it will appear a lot like a plain white flasher bulb

without a dome. To further enhance the effect, position a real flasher close to the bulb, set its

colour to plain white, and disable the

model to make the flasher invisible. Using the FlashForMs script function, flash the flasher with identical para-meters

parallel to the flasher bulb you created earlier. The bulb will now provide the

visual flashing effect while the invisible flasher will light up the whole

playfield and screen, like a dome flasher would if you were using that. You now

have a perfect naked flasher!

For “naked flasher bulbs”,

i.e. flashers without a plastic dome, there’s a neat trick. Simply insert a

normal bulb, make it completely white

and set the radius very high, like 96 millimeters. The white colour and

radius will make this bulb extremely bright. Don’t forget to draw this bulb in front of any object as

you would do it with flashers, so the bright flash will overdraw any objects.

Then flash this bulb using the Flash-ForMs

script function, and it will appear a lot like a plain white flasher bulb

without a dome. To further enhance the effect, position a real flasher close to the bulb, set its

colour to plain white, and disable the

model to make the flasher invisible. Using the FlashForMs script function, flash the flasher with identical para-meters

parallel to the flasher bulb you created earlier. The bulb will now provide the

visual flashing effect while the invisible flasher will light up the whole

playfield and screen, like a dome flasher would if you were using that. You now

have a perfect naked flasher!

3. The Topping: Adding Detail

With a nice foundation to build on, you can now

concentrate on details that will make your table look more realistic on the

surface.

Plastics & Screws:

One thing to know about

plastics is that they are usually not

translucent. They let light shine through and produce shadows of posts and

objects touching them, but you can’t see the playfield below a plastic unless

it’s clear (no artwork printed on it). Many people think they should make their

plastics translucent to get the GI lamps to shine through, but the “reverse drawing” approach gives much

more solid results. For one, you will get a definite light halo on top of your

plastic graphics that nicely brightens them up, similar to the light dots on

the backglass. Secondly, your graphics will remain fully coloured when the

plastic is opaque. It’s very easy to produce opaque plastics with light halos

over them: draw your plastic above the GI bulbs, then send the plastic to the back and turn on ordered halo glow for the bulbs. The halos will now be drawn on top

of the plastic since it’s rendered behind them, and any graphic on it will get

nice light spots as if the plastic was lit from below.

One thing to know about

plastics is that they are usually not

translucent. They let light shine through and produce shadows of posts and

objects touching them, but you can’t see the playfield below a plastic unless

it’s clear (no artwork printed on it). Many people think they should make their

plastics translucent to get the GI lamps to shine through, but the “reverse drawing” approach gives much

more solid results. For one, you will get a definite light halo on top of your

plastic graphics that nicely brightens them up, similar to the light dots on

the backglass. Secondly, your graphics will remain fully coloured when the

plastic is opaque. It’s very easy to produce opaque plastics with light halos

over them: draw your plastic above the GI bulbs, then send the plastic to the back and turn on ordered halo glow for the bulbs. The halos will now be drawn on top

of the plastic since it’s rendered behind them, and any graphic on it will get

nice light spots as if the plastic was lit from below.

When creating a plastic, be

sure to go the same route you went with rubbers: often more shape points produce smoother rounded

corners, and plastics should always be rounded on their outline, never have a

sharp edge on any end. Ideally, the plastic should follow the shape of the

rubber beneath it if there is one. Make sure that posts under the plastic are

centered and that the plastic is not shifted to a side. Plastics on posts

should always start at the height of

the posts, often 29 millimeters. If

you work with star posts, use the Orn-Nut-Spacer

model where possible to get the post height up to 29 mm, then put the plastic

over it and finish up with a nut model

on top. This will create the perfect illusion that the post is fixed to the

playfield with a spacer nut and that the plastic is tightly screwed to the

post. If for some reason you can’t use spacer nuts on star posts, or if you put

your plastic on top of rubber bumper posts, add Orn-Screw models to the plastic to “screw” it onto the posts under

it. Don’t forget the screw/nut texture!

When creating a plastic, be

sure to go the same route you went with rubbers: often more shape points produce smoother rounded

corners, and plastics should always be rounded on their outline, never have a

sharp edge on any end. Ideally, the plastic should follow the shape of the

rubber beneath it if there is one. Make sure that posts under the plastic are

centered and that the plastic is not shifted to a side. Plastics on posts

should always start at the height of

the posts, often 29 millimeters. If

you work with star posts, use the Orn-Nut-Spacer

model where possible to get the post height up to 29 mm, then put the plastic

over it and finish up with a nut model

on top. This will create the perfect illusion that the post is fixed to the

playfield with a spacer nut and that the plastic is tightly screwed to the

post. If for some reason you can’t use spacer nuts on star posts, or if you put

your plastic on top of rubber bumper posts, add Orn-Screw models to the plastic to “screw” it onto the posts under

it. Don’t forget the screw/nut texture!

If you line up plastics along metal wall guides, it often helps to let a little rim stand over

the wall so the plastic fully closes up with it. Make sure your wall guide is

high enough to meet the plastic (default 29 millimeters) and keep in mind that

the default height of the outer playfield

walls is 32 mm. Any plastic you attach to them must have a height of 32 mm and can’t properly meet

with wall guides or posts unless you change the height of the playfield wall. I

ran for a compromise of 30 mm on both the playfield wall and the guides so I

could safely attach the plastic to both, and any posts under it would have a

space of a millimeter which is hardly visible.

Applying screws is not only important on posts. For

example, plastics are often screwed into the metal wall guides when there are

no posts to screw them to. Simply adding a screw near the wall guide will do

the trick. Of course you can also add rubber bumper posts anywhere and screw

your plastics to them. This can be useful if the plastic can be looked under,

i.e. if the trick with the screw near the wall guide doesn’t work.

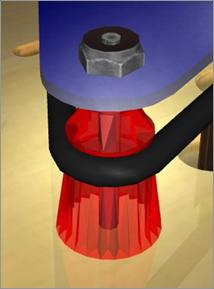

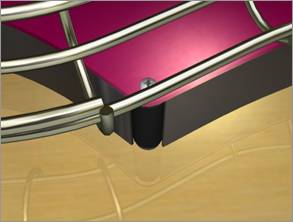

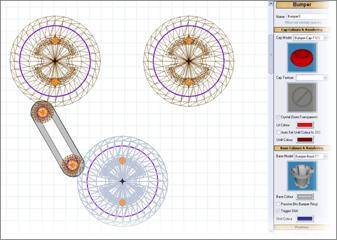

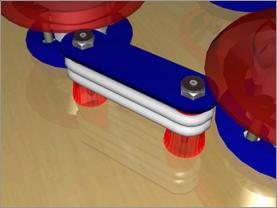

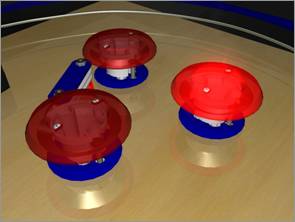

Models like bumpers

and bumper lane guides look much more

realistic with screws on them. For bumpers, place two screws inside the two openings of the bumper base (see picture)

and offset them by 43 millimeters. It

will look as if the bumper cap was screwed to the base. Do the same for lane

guides, placing the guide on two posts (offset

10 mm for thin posts, 8 mm for star posts without spacer nuts) followed by two screws to fix the guide to the posts.

The screws get an offset of 29/31 mm

since the guide is 2 mm thick.

A final detail to add to screws and nuts is random rotation. On a real machine,

naturally not all screws will be rotated to zero degrees, so giving your screws

some random rotation values will make them seem “screwed in”.

Gates & Brackets:

When using a gate, a bracket should be added to hold it.

Brackets and gates look best with the “chrome

silver” sphere map and a colour of 100% white. The gate must be attached to

a surface to get the correct height,

otherwise it will sit inside the playfield. Attaching the gate to the wall next

to it will give it the right height at most times since this wall will probably

be used to attach the bracket as well. Gate brackets are not symmetrical; they have a longer and a shorter screw side and

the longer side is 2 millimeters lower! You cannot place a gate bracket

When using a gate, a bracket should be added to hold it.

Brackets and gates look best with the “chrome

silver” sphere map and a colour of 100% white. The gate must be attached to

a surface to get the correct height,

otherwise it will sit inside the playfield. Attaching the gate to the wall next

to it will give it the right height at most times since this wall will probably

be used to attach the bracket as well. Gate brackets are not symmetrical; they have a longer and a shorter screw side and

the longer side is 2 millimeters lower! You cannot place a gate bracket  on top of two identically high

walls or posts; one of them must be 2 mm higher than the other. A gate bracket

is only 1 mm thick, so add two screws with an offset of 1 mm to the walls or offset them by 28/30 mm when placing

the bracket on posts. This is also a perfect example of when not to use

the spacer nut on a star post: if you

want to have the bracket’s lower end on the post, simply place it directly on

it and put the screw on top, 28 mm high. Since star posts are only 27 mm high

and you’ll want to get the higher end of the bracket to 29 mm, a star post

without a spacer nut is perfect for the lower end. It’s done like this on real

machines too.

on top of two identically high

walls or posts; one of them must be 2 mm higher than the other. A gate bracket

is only 1 mm thick, so add two screws with an offset of 1 mm to the walls or offset them by 28/30 mm when placing

the bracket on posts. This is also a perfect example of when not to use

the spacer nut on a star post: if you

want to have the bracket’s lower end on the post, simply place it directly on

it and put the screw on top, 28 mm high. Since star posts are only 27 mm high

and you’ll want to get the higher end of the bracket to 29 mm, a star post

without a spacer nut is perfect for the lower end. It’s done like this on real

machines too.

A spinner bracket

has the same height on both ends, so when using a spinner bracket, nothing of

the above is required.

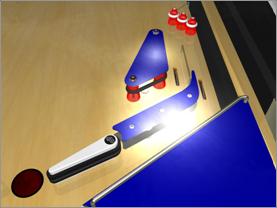

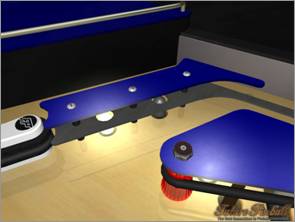

Flipper Lane Guides:

On FP’s default table, the flipper lane guides have no plastics. This would work for early electronics

tables, but all modern pinball machines have plastics on the lane guides, often

one, sometimes two layers. It’s very simple to create plastics for the lane

guides: simply copy the existing metal guides and move the copies up to 27 millimeters. Then increase the height of the lane guide holders so that they touch the plastics and offset the

screws by 29 mm. To make the left plastic more like on a real machine, cut down

the upper left end so that it is on about a line with the upper right end of the

right plastic.

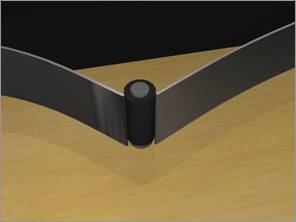

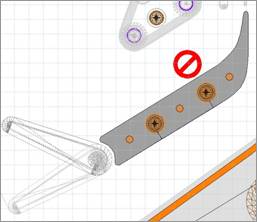

Flipper lane guides often have GI bulbs under and openings in them to let the light shine through.

Creating such an opening is a little work since it requires you to add shape

points inside of the metal. Start with two

points on the upper or lower side of the metal and try to position them so

that they meet on a straight line. Basically the sideline of the metal should

look as if there was no shape point on it at all. Once aligned, use these two

points to cut out a circular hole in

the metal, adding smooth shape points

and forming a ring. See the picture for reference. Then place the GI bulb and

ornament hole under the opening. Send the lane guide plastic to the back (or

the bulb to the front) to get the light halo on top of it.

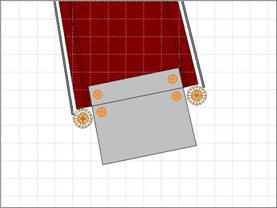

Ramps:

Creating ramps is easy with

FP. Making them look real requires a little creative work. In its current

version FP lacks ramp entrance blades.

It’s easy to create such a blade, though: make your ramp, then create another

ramp (model T2) without walls (set the

wall height to 0). Make its width a little smaller than your real

ramp’s width and set the end height to 2

or 3 millimeters. Make this flat ramp short so that it almost shapes a

square. Apply the “plastic black” sphere

map and move the square slightly above

the entrance of your real ramp. This is your ramp entrance blade.

Creating ramps is easy with

FP. Making them look real requires a little creative work. In its current

version FP lacks ramp entrance blades.

It’s easy to create such a blade, though: make your ramp, then create another

ramp (model T2) without walls (set the

wall height to 0). Make its width a little smaller than your real

ramp’s width and set the end height to 2

or 3 millimeters. Make this flat ramp short so that it almost shapes a

square. Apply the “plastic black” sphere

map and move the square slightly above

the entrance of your real ramp. This is your ramp entrance blade.

To attach the blade to the ramp and the playfield, add four screws as shown on the picture. Offset them so that they appear

correctly on the blade. On a real ramp, the blade is attached with two rivets

that can currently only be simulated by screws. To make the screws look more

like rivets, sphere mapping them is a

good idea. Normally texture the “real” screws that fix the blade to the

playfield.

To make the entrance even more realistic, you can add two rubber bumper posts in front of the

ramp walls. This will ensure that the ball bounces off if it misses the ramp

entrance a little, and it will also prevent the ball from accidentally rolling

under the ramp. Usually you should also use guides or some other form of

blockade around the ramp so the ball won’t get stuck under it.

If the posts are not your style and you want to make

the most use of your playfield space, you can also work with two slim standup (leaf) targets. Put

each target in front of a ramp wall, then rotate them so they line up. Don’t

forget to add round or hammer ornament

holes for the targets. If the holes are too large, you can hide a part of

them under the entrance blade!

Sound:

Sound effects in FP lack a little realism. They are not

bad, but there are better sounds out there. One thing that sounds like it

should are the flippers. Their sound is very close to the real thing and

shouldn’t be changed, but the file

that FP uses has a latency which can

be seen on any stronger flipper strength. I have edited the file and cut out

the latency, and the flippers sound much snappier now. The file is included in

my sample table.

Also, slingshots and bumpers could use better sound

effects. While the slings are okay, just not as snappy as they should be, the

bumpers on real machines either have a much harder click/thump than in FP, or

they feature a plastic sound that kind of “oomphs” a bit. There are some fine

bumper sounds in several mechanical sound

libraries, and these libraries were made with a purpose. Use them and get

your sounds real!

4. Conclusion

If you have tried some of the ideas in this guide, you

have seen how easy it is to add realism to your tables. Of course many details

mean a big polygon count, but since everyone has the option to turn off

ornaments and render objects with less polygons, it shouldn’t pose a big problem.

Future Pinball runs great on many systems today and some added detail shouldn’t

be a performance problem. Enhance your tables!